At sunrise, the rows glow not just with dew but with data. Electric crawlers trace the edges of beds, cameras study leaf veins, and a sprayer hesitates before deciding that this one weed deserves a precise bead of herbicide. The choreography is quiet—no roar of diesel, only the whir and click of sensors doing math on the move. It’s farming as choreography: centimeters matter, milliseconds matter, and each decision about water or nutrients ripples through a supply chain that begins at a root and ends in a city. Autonomous robots and AI-driven precision agriculture are not sci‑fi experiments anymore; they are practical tools that promise fewer losses, less waste, and steadier harvests in an age when the climate tosses dice. They may not feed the world by themselves, but they can tilt the odds.

This morning, a tractor without a driver holds a straight line more faithfully than any veteran operator, its tires threading between seedlings like a practiced dancer. A swarm of knee-high robots flanks it, each with a job: one skims the topsoil, mapping moisture; another uses vision to spot a patch of mildew; a third trims cover crops into a mulch thick enough to shade out future weeds. The farmer watches from the field edge with a tablet, but the choreography does not need him to breathe. He wades in only when the system asks a human to decide whether to spare a weed that feeds beneficial insects.

Tomorrow’s harvest quietly begins in such moments. Once a farm knows itself with this degree of fidelity—leaf by leaf, root by root—it becomes more resilient to the shocks that have made planning a gambler’s game. A heatwave becomes a variable to counter, not a catastrophe to endure. Labor shortages—the unseen drought choking whole sectors—ease when night shifts are photons and code.

When the field itself is a computer, food security stops being a slogan and becomes a geometry problem: how to allocate water, nutrients, and attention so that yield stabilizes even as weather and markets lurch. The story, of course, starts long before the whir of electric motors. A century and a half ago, mechanical reapers yoked horsepower to steel and made one person’s labor count for many. In the mid-20th century, improved seeds and fertilizers widened the aperture again, bringing the Green Revolution’s gains and its long shadow of input dependence.

By the late 1990s, satellites and yield monitors entered the cab; guidance lines etched themselves into soil, and the first generation of precision agriculture taught farmers to treat fields not as canvases to paint uniformly but as mosaics to tile differently. Today’s autonomy is the next turn of that screw: an old promise—more with less—rewritten in code. The robots do not plant or spray at random. High-precision GPS and radio correction fix their position to the inch.

Lidar and stereo cameras give them depth; spectral sensors read the faint fingerprints of stress in leaves, days before a human eye would notice. Machine learning models, trained on seasons of data, weigh the costs of a squirt of nitrogen against the chance a rainstorm will wash it away. They do not spray fields; they spray plants. They do not water acres; they water roots.

The difference shows up in well logs and river gauges, and later, in the balance sheets of farms that no longer push inputs indiscriminately. Under orchard canopies, other machines practice a finer art: plucking fruit without bruising it. They learn from every miss, adjusting grip, angle, and timing across hours of repetition a human body cannot endure without strain. On vegetable farms, lightweight weeders work day and night, their blades flicking at invaders while leaving lettuce untouched.

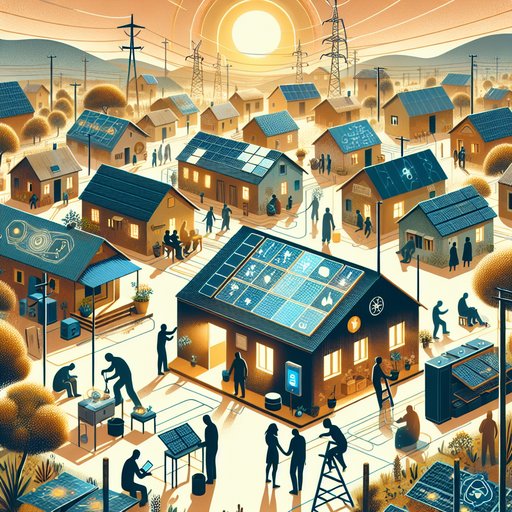

Overhead, small drones sweep low and fast, stitching maps from pixels that double as prescriptions. The language of agronomy stretches to include confusion matrices and inference times, but the outcome is tangible: fewer chemicals, fewer passes, and crops that face fewer invisible insults on their way to the loading dock. The revolution does not belong only to mega-farms. In regions where electricity is sporadic and bandwidth is worse, solar-charged, battery-swappable robots promise a different kind of independence.

Models that once demanded a cloud connection now live at the edge, optimized for the limitations of a dusty field phone. A cooperative might share a fleet, scheduling them like taxis during peak planting. Payment can be seasonal, not upfront, turning autonomy into a service that smallholders can afford. When a machine fails, a local mechanic replaces motors and boards with off-the-shelf parts, following repair guides written for nonengineers and translated into the languages of the field.

With robots, certain practices long considered fussy become practical. Intercropping and living mulches, which ask for attention at the square-meter scale, slot neatly into a system that thinks in square meters. A camera sees the difference between a volunteer and a seedling; a planner knows that the clover strip will feed nitrogen to the crop beside it without starving the row beyond. This is not nostalgia for hand farming; it is the rescaling of complexity, making ecologically diverse systems manageable by trading human exhaustion for machine patience.

The reward is not just yield; it is resilience—the spare tire of agriculture. The data itself becomes a new crop. Daily leaf temperatures feed into models that predict irrigation demand two days ahead; soil nitrate maps stitched over seasons reveal dead zones that need rest, not more fertilizer. A processor can contract with confidence when variability shrinks, reducing price shocks that ripple from fields to supermarket aisles.

Insurance, long a blunt instrument, can become something more nuanced than acreage and county weather reports. There is risk here, too: a farm that cannot operate when a server hiccups is not resilient; a machine that accepts only one brand’s map format is a hostage. The answer lies in interoperability and in the practical politics of ownership—who holds the keys to a harvest’s history. The social ledger must be kept alongside the agronomic one.

Autonomy shifts tasks as much as it removes them. Someone writes the datasets that define “weed” and “crop,” and someone chooses how often a machine pauses to save pollinators. Surveillance by any other name is still surveillance if a field is dense with cameras and microphones. Rural broadband becomes a civil work, not a luxury, and so does the right to repair what you bought.

There are questions of cybersecurity—what a ransom note means when it locks up tractors during harvest—and e-waste, because batteries and boards have their own afterlives. A food system that relies on robots must be honest that resilience is hardware as well as soil. In a farmhouse office, a father scrolls through a heat map of a field his mother once walked row by row with a notebook and a pencil. On screen, the field is not flattened into numbers; it is alive with gradients and anomalies, tiny storms of variation that the robots now chase down and reconcile.

He does not miss the blisters, but he misses the certainty that skill lived only in hands. Then he steps outside at dusk and watches a headland turn neatly on its own, and he feels a different kind of pride: in designing a system that never sleeps and seldom wastes. Food security, at its core, is a promise made and remade every season: bedrock calories, nutrition that travels, prices that don’t punish the poor when a flood hits somewhere they can’t name. Autonomous robots do not fulfill that promise; people do.

But these machines are a way to keep the promise when the weather changes its mind, when labor is scarce, when water is rationed by the day. The field is still a field, and the crop is still a bet. The bet is just better informed, and the odds, for once, are tilted back toward us.